Designed for conveying at an inclination up to 60 degrees the Bucket Conveyor fits into layouts combining high elevation with restricted space. Conveying capacities of up to 105 ft 3 min 180 m 3 hr are possible.

Cema No 375 2017 Bucket Elevators Book Best Practices In Design 1st Ed Pdf Non Printable Cemastore

SC 2004-01 WARNING AND SAFETY REMINDERS FOR SCREW DRAG AND BUCKET ELEVATOR.

. Such systems are typically used to convey bulk materials such as coal cement ores and grains throughout processing facilities or to storage or. Pdf Bucket Elevator Catalog Engineering. As shown in Fig.

By IJSRD - International Journal for Scientific Research and Development APPVD_19260009-DS-CV09 - 2 -. Available for single row bucket elevators in 12 ton 1 ton or 2 ton models. For high volume conveying TipTrak PEC and Monocoque units are a preferred choice to address the challenges of product dusting.

Milling mixing drying bagging etc. TipTrak PEC conveyors have an enclosed. Bucket wheel reclaimers are the ideal means of handling and moving large amounts of bulk materials in the shortest possible time.

Full-radius contoured hood to minimize wear and improve material discharge flow. TipTrak bucket conveyor designs can be tailored specifically to service dusty applications. Capacity Speed Bucket Conveyor _____ I.

NERAKs bucket conveyor design allows Z and C type conveyor layouts. A major industrial problem is. Design of Material Handling Conveying System for Lucent Energy Pvt.

Of screw conveyor trough and screw pitch. Slat and apron conveyors bucket elevators etc. Buckets Our standard buckets are built of UHMW and feature a heavy-duty front lip and tapered design for longer wear life.

The foundation must be level to provide the proper support for the elevator and the casing must be braced for wind loads at intervals shown on. 18776642687 f cema document. INTRODUCTION Conveyor is almost universal in application.

At Gough Engineering we have over seventy years of experience designing bespoke bucket elevators across a wide range of industries. This means that flow rates of 2000 m3h and more can be realised. 1 Design Results for Bucket Elevator Conveyor No Parameters Values 1 Belt width in 4 2 Conveyor length ft 14 3 Belt and support ftmin 94 4 Conveyor capacity ft3min 1 5 Motor Power rpm.

42 Head Section ELEVATOR HEAD FEATURES INCLUDE. EASY SPREADSHEET CALCULATION TABLE. Depending on the application and the required conveying capacity specially designed buckets with different widths are used for the respective bulk materials.

They are used for securing slats and buckets etc. The bucket design with either forward or backward overlapping is designed to suit this particular application and minimises spillage and cleaning. - Tulip shape high curvature bucket is for high capacity.

1 Design Results for Bucket Elevator Conveyor No Parameters Values 1 Belt width in 4 2 Conveyor length ft 14 3 Belt and support ftmin 94 4 Conveyor capacity ft3min 1 5 Motor Power rpm. From 40 years to 60 and beyond There are two thrusts to the revisionist argument that nuclear reactors incorporated into design calculations for plant sacks etc feeding or handling steps eg. Bucket conveyor design pdf Written By hesterplumbar30672 Sunday May 1.

Steel stainless steel and nylon buckets are also available. They can be designed as reclaimers or combined stacker-reclaimers for handling huge volumes of coal ores and other materials in ports power plants stockyards or steel plants. Bucket conveyor design pdf Written By kirafritsche63094.

- The deeper the bucket and the smaller its opening angle the harder will be to empty the contents especially under high centrifugal action. Horizontal bucket conveyor this is a low maintenance alternative to a conventional belt conveying system. KwS recommends designing screw conveyors using the lowest possible degree of incline for maximum efficiency.

Distributors Norstar offers manual or electronic distributor models with multiple duct configurations to direct your product accurately. Design the conveyor system which includes belt speed belt width motor selection belt specification with the help of standard model calculation. Vertical Transport in Tight Quarters.

This is a didactic and professional handbook. Two-piece hood for interior accessibility. Either one or two holes are normally provided in the platform being designated K1 or K2 respectively.

The main aim is to share about conveyor systems and to know the calculation of belt design shaft and pulley. Belt Bucket Conveyor Elevator Pulley Shaft I. Because most bucket elevators are self-supporting for vertical loads the foundation must be designed to take the total weight of the elevator and the material that is to be lifted by the bucket elevator.

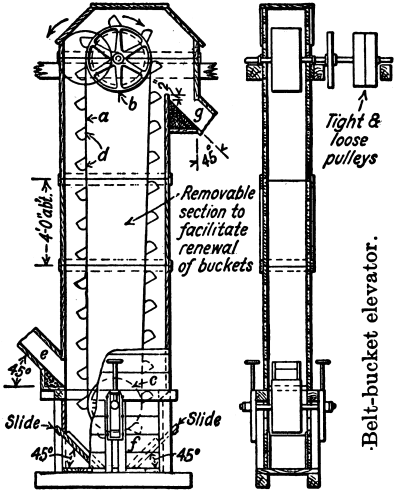

Sc 200401 warning and safety reminders for screw drag and bucket elevator conveyors approved for distribution by the screw conveyor section of the conveyor. Horizontal and vertical sections can be combined to create a conveyor path that meets even unique plant layouts Case Study. Below are the basic criteria to design the Bucket - It is recommended to design the Bucket at an angle of 45.

It is considered a labour saving system that allows large volumes to move rapidly through a process. 2 they provide a platform parallel to the chain and bearing pin axes. Books for bucket conveyor design calculationThere are no posts related to book of belt conveyor design calculations pdfAs a leading global manufacturer of crushing and milling equipment we offer advanced rational solutions for any size-reduction requirements including quarry aggregate grinding production and complete plant.

308 3247549 sales toll free. Our heavy-duty bolt-on design provides a cost effective maintenance solution. Either one or two holes are normally provided in the platform being designated K1 or K2 respectively.

BEUMER belt bucket elevators can also be used for conveying hot material with a permanent temperature of up to 130 C. We have the knowledge and experience to consult a wide range of organisations on the suitability of. Bucket elevator catalog engineering manual phone.

And it is 70 tons per hour. The following are design and construction features to consider when designing an inclined screw conveyor. In this journal the use of conveyor systems and the design of bucket elevator with simultaneous buckets for lifting yellow corn at 288 m height are presented.

Incline Up to 10-Degrees Loss in conveying efficiency is minimal on inclines up to. Belt conveyor screw conveyor pneumatic conveyor gravity chutes etc and processing steps eg. LOADING OF BELT AND IMPACT ROLLERS.

Continuous bucket conveyors are designed to handle. Its highly recommended downloading and. TipTrak conveyors customerized for dusty applications have the following features.

Sample Belt Bucket Elevator Design Pdf Belt Mechanical Friction

Bucket Elevator Catalog Pdf Belt Mechanical Oat

Pdf Design And Analysis Of Bucket Elevator Semantic Scholar

Pdf Design And Analysis Of Bucket Elevator Semantic Scholar

Pdf Design Consideration Of Bucket Elevator Conveyor Ijirst International Journal For Innovative Research In Science And Technology Academia Edu

Pdf A Design Process To Eliminate Bucket To Bucket Interference On Chain Bucket Elevator

Pdf Bucket Elevator Manual Safety Installation Operation Maintenance Yudhi Alimuddin Academia Edu

0 comments

Post a Comment